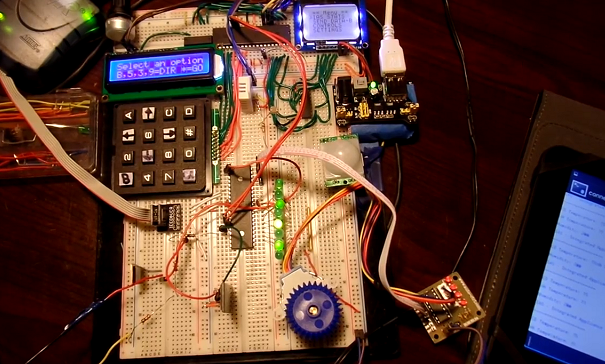

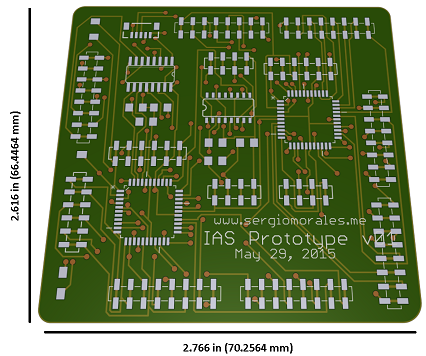

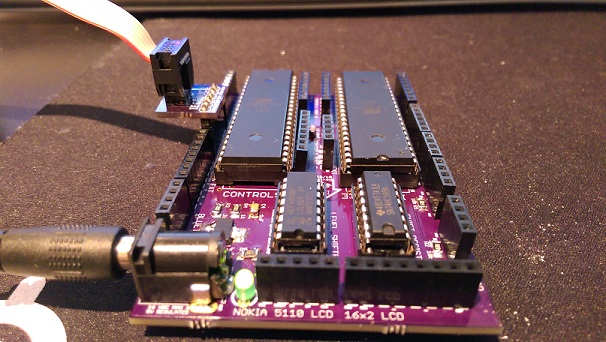

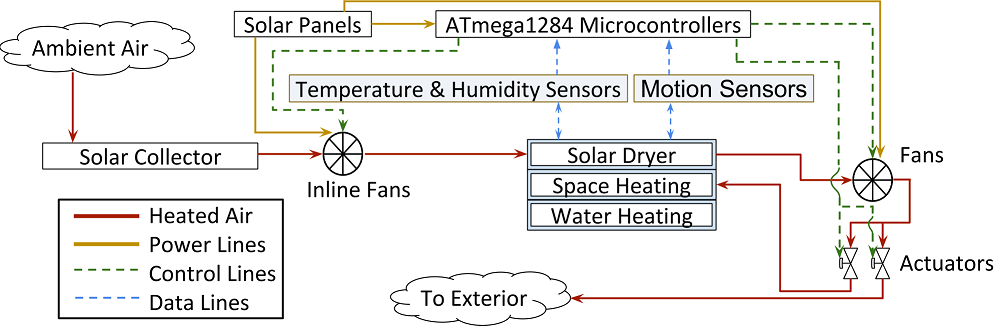

The general flow for what the control system of the IAS consists of.

Working in such an interdisciplinary team has been great. My main motivation behind working in such a project was the real pratical experience I've gotten from it. Coming up a design, explaining it to other engineers from other fields, and brainstorming ways on optimizing or totally redrafting components is something you can't learn in a classroom. Plus, we've proven just how many people's interests have been peaked by introducing such a sustainable project.

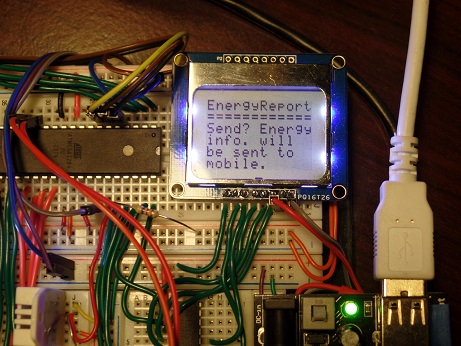

All in all, the IAS is different from just hanging up your laundry on a clothesline. We're able to come up with wrinkle-free, faster, and more affordable was of drying your clothes, aside from also heating up air and water, which is a great plus as well. From looking at the diagram, the use of microcontrollers allow to add on so much more to the system, such as wireless actuation of the appliances through Bluetooth, which will be discussed later.